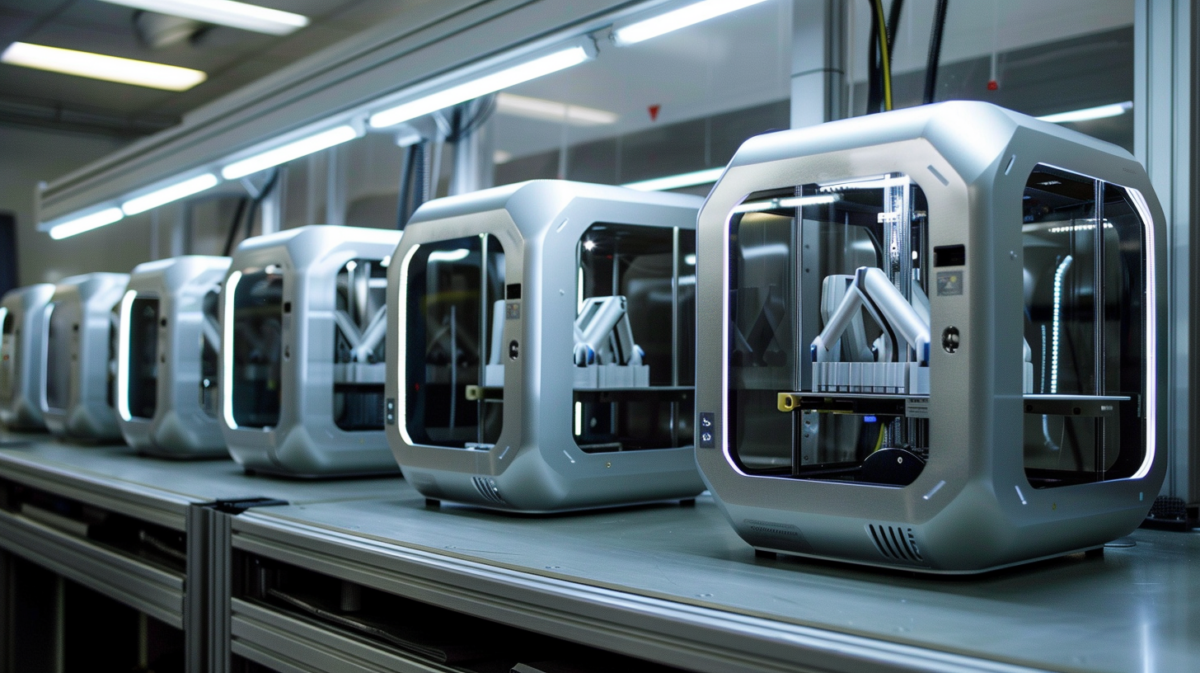

Traditional supply chains can involve multiple steps and logistical hurdles. But what if there was a way to simplify production, reduce lead times, and gain a competitive edge? Enter 3D printing, also known as additive manufacturing. This technology offers a transformative approach to bring products from concept to customer.

Understanding Traditional Supply Chains: A Complex Journey

Imagine a typical product you source. It likely travels a significant distance, involving various stages like design, component manufacturing, assembly, and shipment. Each step necessitates different facilities and specialists, making the process intricate and time-consuming.

3D Printing: The Disruptive Force

3D printing disrupts this traditional model. It utilizes a digital file to create objects layer by layer, enabling the production of complex geometries without relying on conventional tooling. This translates to several advantages for businesses:

On-Demand Manufacturing: Produce parts or products only when required, eliminating the need for large production runs and excess inventory. This reduces storage costs and the risk of obsolescence.

Localized Production: Bring production closer to your customer base. This minimizes transportation time and expenses while offering quicker response time to regional demands.

Streamlined Operations: Consolidate complex parts into single, 3D-printed components. This simplifies assembly processes and reduces the number of parts required in your inventory.

Taking Action: How to Integrate 3D Printing into Your Supply Chain

Here’s a roadmap to leverage 3D printing within your organization:

1. Technology Exploration: Comprehend 3D printing’s capabilities and limitations. Identify areas where it can complement or even replace traditional manufacturing processes.

2. Product Evaluation: Analyze your product portfolio to determine suitable applications for 3D printing. It might be ideal for prototypes, low-volume production runs, or specialized components.

3. Pilot Projects and Learning: Start small. Experiment with 3D printing a few parts or products to assess its feasibility and identify any challenges.

4. Partnering with Experts: Collaborate with 3D printing specialists. Their expertise can aid you in optimizing designs, selecting materials, and maximizing the benefits of this technology.

The Future is Additive:

3D printing holds immense potential to transform supply chains. It offers on-demand, localized production, and streamlined operations, empowering businesses to be agile, efficient, and cost-effective. As 3D printing technology matures, we can expect even more innovative applications that will reshape the future of manufacturing and supply chain management.

Addressing Common Concerns: A 3D Printing FAQ

Q: Can 3D printers create anything?

A: While 3D printing offers a wide range of possibilities, there are limitations in size and materials. However, the scope of printable objects is constantly expanding.

Q: Is 3D printing eco-friendly?

A: It can be! 3D printing often uses less material and reduces transportation needs, leading to a potentially smaller environmental footprint. The specific materials used for printing also play a role in its sustainability.

Q: How fast is 3D printing?

A: Printing times vary. Simple objects can be printed in hours, whereas intricate designs might take days. 3D printing excels in creating prototypes and small batches.